Configuration

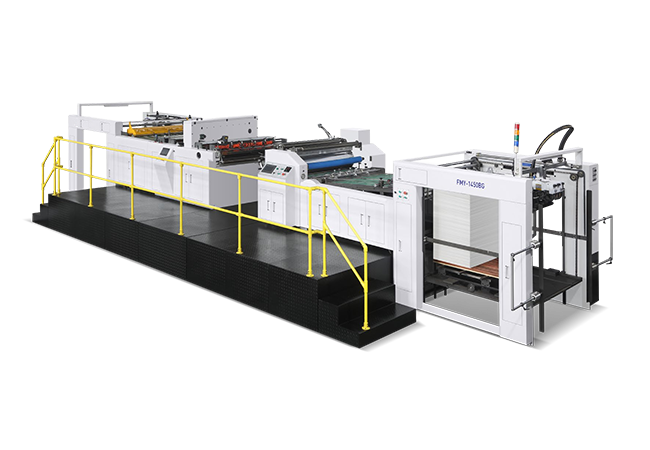

| Model | FMY-1700BG |

| Max. Paper Dimensions | 1700*(L) |

| Min. Paper Dimensions | 400*400 |

| Paper Thickness | 100-500 |

| Laminating Speed | 20-120m/min |

| Overall Power | 46kw |

| Overall Dimensions | (L)*5.5*1.8 |

| Overall Weight | 13.5T |

| L | L4 |

| Paper Dimensions | 1680MM |

| Overall Dimensions | 11 |

Introdution

- Non-stop paper feeding and paper delivery functions, fast lamination speed, and high-precision servo motor control for the edge lap mechanism.

- The chrome-plated roller is used for gluing, which saves the amount of glue and ensures even gluing.

- The hot pressing roller adopts electromagnetic heating system, with uniform temperature and good constant temperature, which can meet the high quality requirements of lamination.

- With automatic hydraulic pressure, the operation is easy and convenient. With chain knife, it can slit PET film.

- Humanized design, easy to operate, man-machine interface, clear on the screen in case of failure.

- Product Parameters

- Factory

- Cooperative Partener

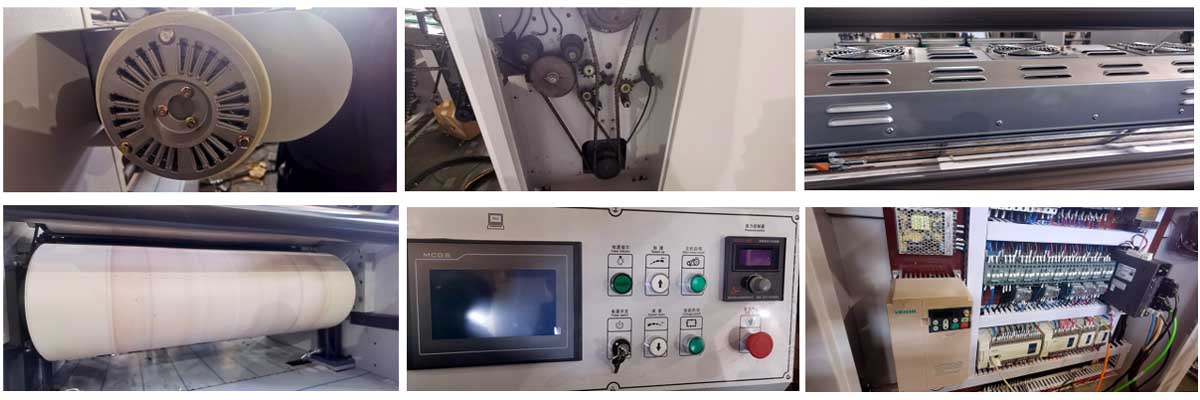

1.Automatic Paper Feeder

- High-speed feeder head, speed 12500 sheets/hour

- The function of non-stop paper loading makes production more efficient and reduces waste.

- Configure 4 suction and 4 feeding suitable for different paper

- Equipped with German Beck air pump, large suction and less noise

- Optional shaftless drive feeder, it is more convenient to adjust large size paper, and the paper feed is more stable

- The paper feed head is equipped with a limit switch and a top paper limit to prevent operation errors from topping the paper feed head

- The paper feeding table board adopts the downward suction type paper feeding, the paper positioning is accurate, and the paper feeding is stable.

- Integral pinch roller design makes the adjustment faster and more convenient when changing specifications.

2.Composite Host

- Thickened (25mm) machine wall panels and stiffener connections make the machine run more smoothly

- Imported Italian brand hydraulic pump (Buvigilon), with stable pressure

- Press-fit copper roll adopts electromagnetic heating + liquid constant temperature method, which can not only achieve rapid heating, but also reduce energy consumption

- The film release is fixed by the air expansion shaft, and the position of the release film can be fine-tuned left and right, front and rear, making the operation more convenient and fast

3.Slitting Machine

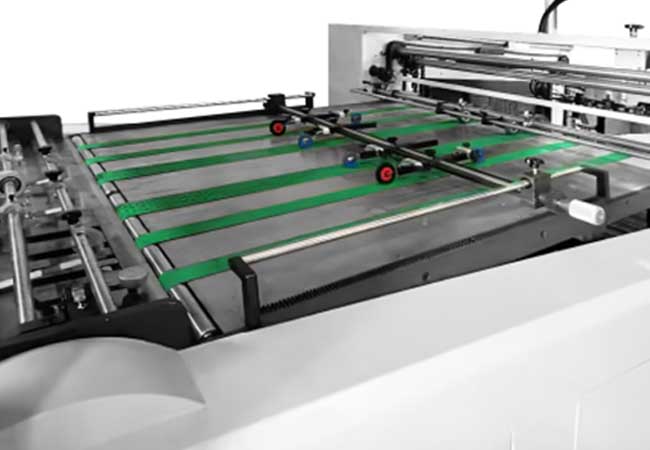

- The multi-function recurve device can ensure the cutting effect of different papers. In the production of ultra-fine paper, a double-recurve device can also be installed as an option.

- Advance paper pressing roller adopts multi-segment pressing roller, and can use sandpaper slitting process on it, which can meet more production processes

- The whole machine adopts a variety of slitting methods, which can be selected according to different production requirements (abrasive cloth knife slitting, disc knife slitting, chain knife slitting, and optional hot knife slitting).

- The fully intelligent chain knife slitting system can automatically adjust the slitting position according to the change of the paper, making the operation simple and zero loss

- Large transmission sprocket and high-precision chain rail design, no noise when running at high speed, and small paper can also achieve smooth cutting effect at full speed

- The design of the pneumatic springing and breaking method makes the operation simple and convenient, making the size of the fuselage smaller.

4. Automatic Take-Up Machine

- Lengthen the design of the delivery platen, so that the paper can fully dissipate heat and the laminated paper is more flat

- Automatic double-sheet discharge device, when the paper cannot be cut, it will automatically discharge the delivery paper stack, and will not cause paper jams and losses

- Flushing, the design of blowing up and down can effectively protect the surface scratches caused by rubbing against each other during the production process, and at the same time, it can also make the Pu paper neatly arranged.

- Paper paper plus front flapping paper design to make the collected paper more tidy

- Optional automatic plate changing device, which can automatically complete the operation of changing the paper stack without deceleration, saving manpower more effectively.

Sample

- Laser Film

- Aluminized Film

- FilmBOPP Film

- PET Film

Related Product

Poland SanLin Machinery Co., Ltd. is a professional manufacturer of mechanical equipment. The company has strong independent research and development capabilities, and through the standard, refined quality management system, strict quality inspection, the whole process of SPC management, to ensure the high standard of each component.

Our Service

Perfect quality, continuous innovation, quality service, honest customers “are the main purpose of SanLin , because of this, SanLin has a strong growth. In line with the concept of excellence, we have strict control from material selection to manufacturing and after-sales service.

We warmly welcome friends at home and abroad to discuss cooperation.